Exploring Bicomponent Fiber: The Future of Smart and Sustainable Textiles

In the world of modern textiles, bicomponent fiber is emerging as a game-changer, offering innovative solutions that blend performance, sustainability, and versatility. As industries increasingly look for advanced materials to meet evolving needs, bicomponent fiber stands out for its unique structure and exceptional properties.

What is Bicomponent Fiber?

Bicomponent fiber, often referred to as bico fiber, is a type of synthetic fiber composed of two different polymers spun together to form a single filament. These polymers can vary in terms of chemical composition, melting point, or functionality, allowing manufacturers to create fibers with highly specialized characteristics. The two polymers are typically arranged in configurations such as side-by-side, core-sheath, or island-in-the-sea, each offering distinct advantages depending on the intended application.

Key Benefits of Bicomponent Fiber

The dual-polymer design of bicomponent fibers brings a multitude of benefits:

Enhanced Functionality: Bico fibers can offer a combination of strength, softness, elasticity, and thermal bonding, making them suitable for a wide range of end uses.

Thermal Bonding Capability: Many bico fibers are used in nonwoven fabrics for their excellent thermal bonding properties, reducing the need for additional adhesives.

Customizable Properties: By selecting different polymer combinations, manufacturers can tailor the fiber to specific performance requirements such as moisture-wicking, quick-dry features, or biodegradability.

Improved Processability: Bicomponent fibers can enhance the efficiency of downstream textile processes due to their versatile behavior under different manufacturing conditions.

Applications Across Industries

Bicomponent fibers are widely used across various industries including hygiene, automotive, apparel, filtration, and home textiles. Their ability to provide both mechanical strength and softness makes them ideal for hygiene products like diapers and sanitary napkins. In automotive and industrial applications, these fibers contribute to lightweight and durable composites. Apparel brands utilize bicomponent fibers to improve comfort, fit, and performance in clothing.

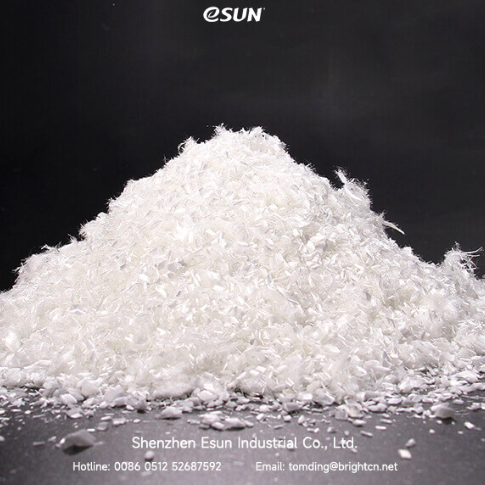

Environmental Benefits and PLA Bi-component Staple

With growing emphasis on sustainability, the textile industry is increasingly turning to biodegradable and bio-based materials. One significant innovation in this realm is the PLA Bi-component Staple fiber. PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. When used as one of the components in bicomponent fiber, PLA contributes to reducing environmental impact without compromising on performance.

PLA Bi-component Staple fibers combine PLA with another polymer, often to improve thermal bonding or mechanical strength while maintaining biodegradability. These fibers are particularly valuable in applications where environmental safety is crucial, such as in disposable hygiene products, eco-friendly packaging, and biodegradable nonwovens. They also offer excellent hand-feel and breathability, making them suitable for sustainable fashion and home textile products.

The Role of Innovation in Bicomponent Fiber Development

The development of bicomponent fibers is a testament to how innovation drives the textile industry forward. Advances in polymer chemistry, spinning technologies, and application-specific design continue to expand the possibilities of what bicomponent fibers can achieve. From heat-shrinkable yarns used in shaping garments to thermally bonded nonwovens used in medical textiles, the potential applications are vast and growing.

New developments are also focusing on creating recyclable and fully biodegradable bico fibers, pushing the industry toward a more circular and environmentally friendly future. Research into renewable raw materials and energy-efficient manufacturing processes is helping to position bicomponent fibers as a leading solution for sustainable textiles.

Future Outlook

The future of bicomponent fiber technology looks bright. With increasing consumer demand for products that are not only high-performing but also eco-conscious, the adoption of bico fibers is set to rise. The integration of smart functionalities such as temperature regulation, moisture management, and even embedded sensors opens new doors for high-tech textile applications.

Industries that prioritize both performance and sustainability—such as healthcare, fashion, automotive, and industrial manufacturing—are expected to invest heavily in bicomponent fiber technologies. As more stakeholders in the textile supply chain embrace this innovation, the global impact of bicomponent fibers will continue to expand.

eSunplafiber: Leading the Way in Sustainable Bicomponent Fiber Solutions

As one of the pioneers in the sustainable fiber industry, eSunplafiber is at the forefront of developing and manufacturing high-quality bicomponent fiber products. With advanced production capabilities and a strong commitment to eco-friendly innovation, eSunplafiber offers a wide range of solutions tailored to meet the demands of modern applications. Their dedication to research, quality, and sustainability ensures that they remain a trusted partner for industries looking to embrace the future of smart and responsible textiles.

Comments

Post a Comment